|

Tack welding and Distortion

What is welding distortion?

You will be shocked, at how powerful distortion can be.

Welding distortion is when the welding is completed and starts cooling down from 1440 degrees C. As the welding starts cooling down it contracts, shrinking slightly, causing a powerful pulling action as it starts cooling down.

This can be compensated for in a number of ways.

Either offset the angle of the workpiece, so that once the weld has cooled down, it will end up in the position you want after distortion, or, weld on the opposite side of the original weld to pull it back in opposite direction.

Alternatively, while it is still hot and cooling down, hit the workpiece with a hammer to bend it into the angle you require.

Depending on the amount of welding required, you need to keep an eye on the movement and compensate for the distortion. You need to constantly alternate your welding from one side of your workpiece to the other, to create an even pull from the welding, preventing further distortion, constantly checking, and measuring your workpiece.

Always align and tack weld what you are about to weld.

Magnetic supports:

You can buy yourself some 90 degree magnetic angle support braces which work very well but, be carefull to remove them away as soon as you have completed the tack weld, because magnets loose their magnetic strength when heated up to high temperatures. The same goes for using a magnetic spirit level. Be careful not to let the magnets get too hot.

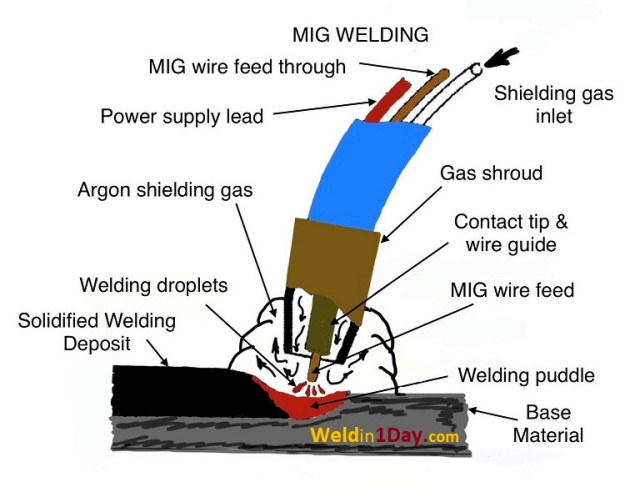

This image shows a bad MIG weld where oxygen has crept in and contaminated the weld. The oxygen creates bubbles in the weld which weaken and compromises the strength of the weld.

When this occurs, you need to grind or cut the weld out completely, and start again.

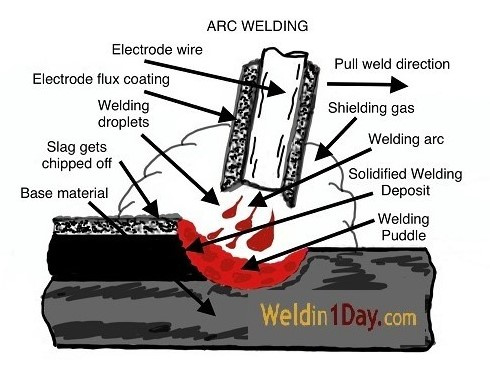

This seldom happens with Arc welding, because the gas is instantly created and present at all times.

MIG welding however is susceptable to this happening occasionally. If you have wind blowing around you it will more than likely blows the argon gas away.

Or, if you happen to run out of gas.

Also, if the gas flow-rate is not set high enough, or if you happen to pull the MIG welding torch away too far from the welding puddle.

It could also happen if the angle of the welding torch is incorrect plus moving in the wrong direction but, this will all be explained in detail later on in the course, to prevent it from happening to you.

Discover all the information needed to become a

proficient welder in our Weldin1Day course.

Introductory price offer for only $297 US

That's 50% off the original price.

We had our minds set on $594 for the long months

of hard work structuring this valuable

and useful information together.

Price increase to $594

once the offer is over.

You are welcome to leave your details to contact you

once the course is completed.

Here is some free information to get you started:

1. Weld in 1 Day introduction.

2. Arc Eys - H&S

3. Stick welding vs Mig welding

4. Welder Shielding Gas

5. Best Beginner Welder + Preparation

6. Best Welders for Beginners

7. MIG and Arc Setup

Cracked motorcycle crankcase repairs

Welding course material.

8. Weave straight line welding.

9. How to MIG weld successfully.

10. How to Arc weld successfully.

11. How to vertical up weld. MIG & Arc.

Weld in 1 Day™ Weld in 1 Day©

|

To enhance your user experience on our website, this site uses cookies.

If you continue to browse, you accept the use of cookies on our site.

See our Privacy Policy

for more information.

To enhance your user experience on our website, this site uses cookies.

If you continue to browse, you accept the use of cookies on our site.

See our Privacy Policy

for more information.