|

We would like to take this opportunity to thank you for purchasing this very comprehensive video welding course. We certainly hope you enjoy the contents but most importantly, we hope you become a proficient welder and enjoy the process of learning a new skill-for-life.

All the best.

Deon van Rooyen and the Weldin1Day team.

Learn to Weld

is a lot easier than you might think,

especially if you are shown and guided

every step of the way

Weld in 1 Day™ Weld in 1 Day©

Here is some free information to get you started:

1. Weld in 1 Day introduction.

2. Arc Eys - H&S

3. Stick welding vs Mig welding

4. Welder Shielding Gas

5. Best Beginner Welder + Preparation

6. Best Welders for Beginners

7. MIG and Arc Setup

Free Bonus material:

Cracked motorcycle crankcase repairs

We assume you have already gone through all the information shown above, which forms part of this welding course.

If not, we suggest starting at the beginning and go through all the information before continuing.

Welding course material.

8. Weave straight line welding.

9. How to MIG weld Successfully.

10. How to Arc weld Successfully.

11. How to vertical up weld. MIG & Arc.

Weave, Straight Line Welding

Arc welding is referred to in different ways.

Arc Welding - Stick Welding - MMA welding.

In order to achieve the exact same results as

shown in our videos. Just follow every step

in our welding courses, and you WILL

achieve the exact same results!

Strong and perfect looking welds

MIG welding vs ARC welding comparisons

|

ARC Welding:

Needs chipping and changing rods.

More difficult to get it to flow evenly.

No gas required.

Easy to use on a construction site.

Works under all conditions.

Welding rod can be bent.

Not practical for spot welding.

Difficult to weld thinner material.

Practical to use a variety of different types of welding rods.

Difficult to weld aluminium.

Cheapest welding machine.

Exceptionally light and compact.

|

MIG Welding:

Faster welding rate.

Continuous wire feed.

Easier to learn.

Needs Argon gas to work.

Not practical on a construction site.

Very difficult in the windy conditions.

Difficult to get into tight positions.

Can be used as a spot welder.

Easier to weld thinner material.

Not practical to use for different types of welding wire.

Easier to weld aluminium.

More expensive to buy.

Bulkier machine + gas bottle.

|

Weave, Straight Line Welding

The difference between a push and a pull weld.

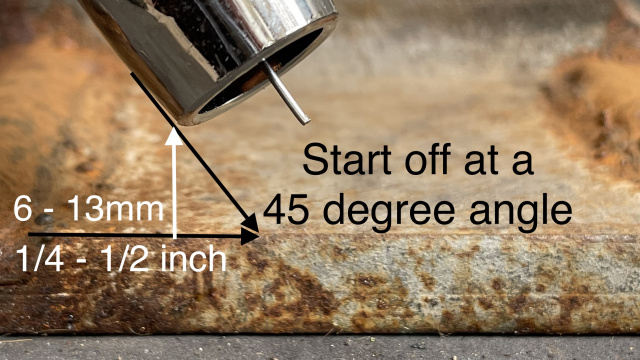

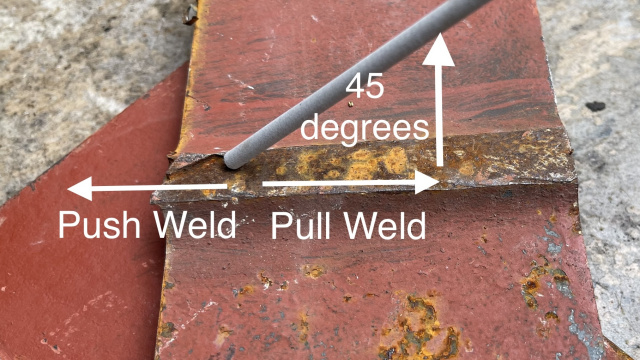

Pull welding is when you start welding with the welding rod, or MIG welding torch at say a 45 degree angle, then drawing it along slowly in the direction of where you require the welding.

We make reference to Arc and MIG together because they share a lot of similarities.

MIG welding is generally speaking a push weld, as shown in the photo, slowly moving the MIG torch in a pushing action.

Making sure to maintain a height of 6-13mm (1/4" - 1/2" inch) above the welding puddle.

The reason for push welding when you are MIG welding is because of the argon gas flow, which creates an oxygen free pocket around the welding area. There is more gas flow in front of the torch as it flows out compared to the back of the torch, ensuring a good weld.

Explained in more detail in section 4. Welder Shielding Gas

IMPORTANT:

Another important tip is not to look at your welding from directly behind the MIG torch or welding rod holder.

Very important to look at your welding progress from the side to keep an accurate eye on the distance away from your welding puddle and importantly, to keep an eye on the welding puddle. Not to advance too fast or too slow from the welding puddle.

The argon shielding gas when holding the MIG torch at a 45 degree angle might allow oxygen in when MIG welding if you are performing a pull weld. If you are holding the torch in a more upright position as shown in the picture then it is acceptable to run in either direction. Pull or push. But generally speaching, MIG is a push weld action.

The photo shows perforation in the weld. Small bubbles are created in the weld. This is caused when you pull the MIG torch away too far from the welding puddle, or if you are welding in windy conditions when the argon gas is blown away while you are welding.

This weld was ground flat to expose and show what is going on underneath the surface of the weld.

Arc welding on the other hand, can run in any direction because the shielding gas is created directly from the flux coating around the welding rod.

You can also successfully weld in windy conditions. That is why arc welding is the preferred method of welding on a construction site because of its practicality.

Important point to remember:

Now. Not to get confused or mistaken with push and pull welding. If you were to twist the MIG torch or welding rod around and point it towards you, that would still be a push weld because it has nothing to do with your body position. It's the angle of the torch or welding rod that defines whether it's a push or pull weld.

How to achieve really good looking welds:

This is an extract from a previous section of this course:

Section 5. Best Beginner Welder plus preparation.

The more controled, precise, steady and accurate your movements are while welding, the better your welding results will turn out.

You need your movements to be like a machine.

It is so satisfying, when you achieve a really good looking weld. And just as satisfying when the flux just drops off when you are Arc welding, as shown in the photo.

You don't get any flux coming off your welds when using an Argon gas MIG welder.

You do get flux chipping off when using gass-less MIG welding called flux core MIG welding, but we do not cover this, because we do not recommend it.

Welding for Beginners.

The clarity of our HD welding videos

are a great help to be able to explain,

teach & show every move, without

overexposed filming footage.

We go into great detail in our advanced welding course, showing the effects of different angles of the welding rod, or MIG welding torch angle.

XXXXXXXXXXXXXXXXXxXXXXXXXXXXXXXXXXXXXXXXXX

We also show/teach you how to achieve welds stronger than the material itself.

Welding techniques:

The zig zag or weaving from left to right is a pretty common technique used as shown in the sketch and illustrated in the video.

Here is some free information to get you started:

1. Weld in 1 Day introduction.

2. Arc Eys - H&S

3. Stick welding vs Mig welding

4. Welder Shielding Gas

5. Best Beginner Welder + Preparation

6. Best Welders for Beginners

7. MIG and Arc Setup

Cracked motorcycle crankcase repairs

We assume you have already gone through all the information shown above, which forms part of this welding course.

If not, we suggest starting at the beginning and go through all the information before continuing.

Welding course material.

8. Weave straight line welding.

9. How to MIG weld Successfully.

10. How to Arc weld Successfully.

11. How to vertical up weld. MIG & Arc.

Weld in 1 Day™ Weld in 1 Day©

|

To enhance your user experience on our website, this site uses cookies.

If you continue to browse, you accept the use of cookies on our site.

See our Privacy Policy

for more information.

To enhance your user experience on our website, this site uses cookies.

If you continue to browse, you accept the use of cookies on our site.

See our Privacy Policy

for more information.